Audio Intro:

5th April 2024:

I’ve just taken delivery of a vintage Tandberg Series 3000X reel to reel tape deck, thanks Cliff. The recorder does work but it needs a good service, which I will carry out soon. I have some Singer Sewing Machine oil which will be ideal for the bearings etc. I’ve ordered a couple of new drive belts but it could also do with a new idler wheel which is 58mm OD. There are none on ebay so I might have to glue a square-section rubber tyre onto the wheel. I’ve done that before with great success. Something else I need is a 5 pin 180 degree DIN plug. I’ve not used DIN plugs for years but, as luck would have it, I’ve just found one amongst my bits and pieces!

The series 3000X was first released in 1970. It was available in either half or quarter-track versions and had four heads, erase, record, play and cross-field bias, a single motor and three speeds. I’ll be adding more info and photos soon.

Below: the Tandberg Series 3000X.

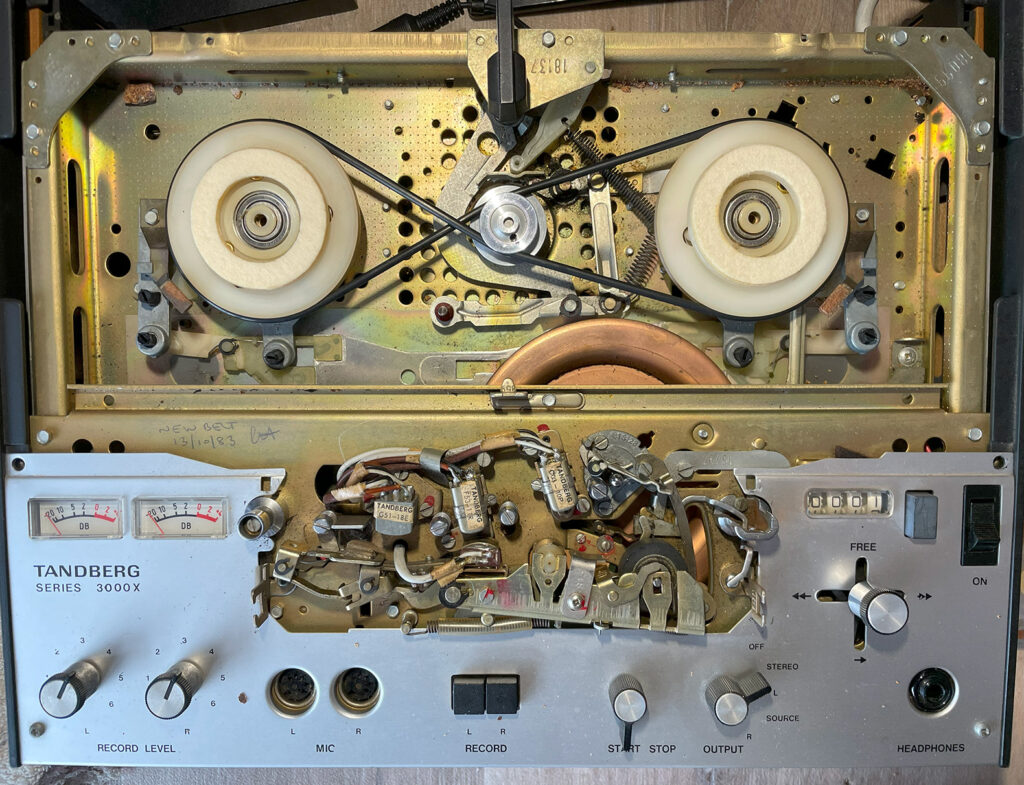

Below: Top cover removed.

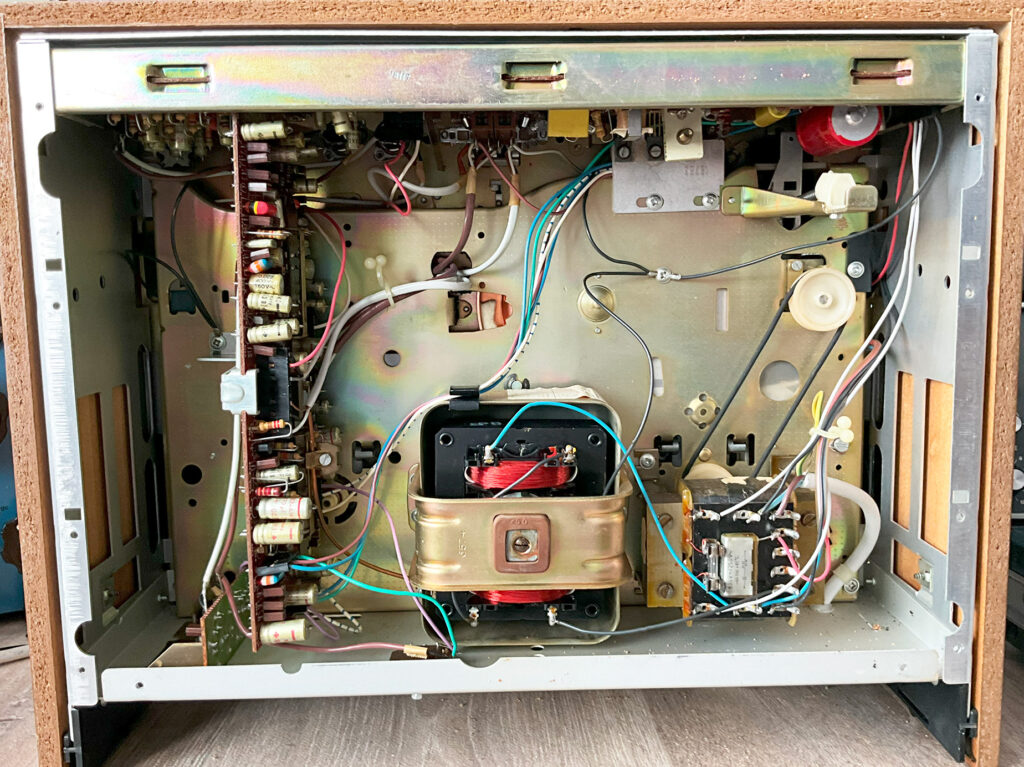

Below: Underside of deck.

Below: Drive system.

The main drive belt is easy to change and the drive system is basic. No need for Philips-type linkages, cams, gears, Bowden cables, levers and the like.

Below: Clutch problems.

As you can see from the photo below, the cork clutch pads have disintegrated. I’ve ordered a sheet of 4mm high density cork. It won’t be easy but I’ll try and cut out new pads and glue them in place on both spool carriers.

Below: Clutch pads.

The sheet of 4mm high-density cork has arrived. The new cork clutch pads have been carefully cut out by my wife. She has patience, unlike me!

Below: Clutch pads fitted.

The new pads fitted. Slightly rough edges but that won’t be a problem.

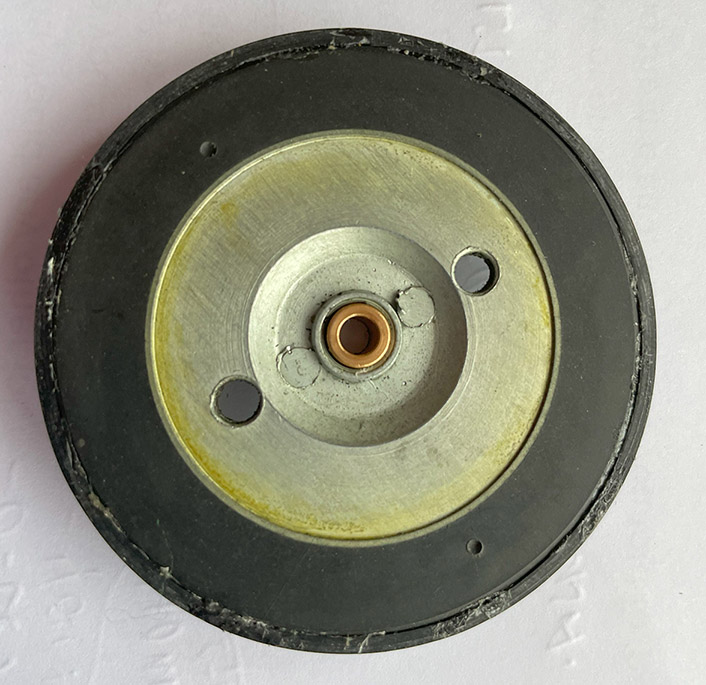

Below: Idler wheel problems.

The rubber has hardened over the decades, causing slipping and noise problems. I’ve glued a square-section rubber belt over the wheel to act as a soft tyre. As it’s a true idler wheel, not part of a gear train, the slight increase in its diameter doesn’t matter. The glue needs to be cleaned off before refitting the wheel. I’ve used this method on many record player idler wheels with great success.

Below: Pinch wheel problems.

The pinch wheel rubber has perished. The old rubber tyre comes off quite easily, see photo. I’ve ordered a new tyre from a chap in Greece. Hopefully, it will be a good fit. There’s rather a lot of dust and debris around the head assembly. I’ll clean this up before refitting the pinch wheel.

1st May 2024:

The pinch wheel rubber tyre has arrived from Greece! Watch the video…

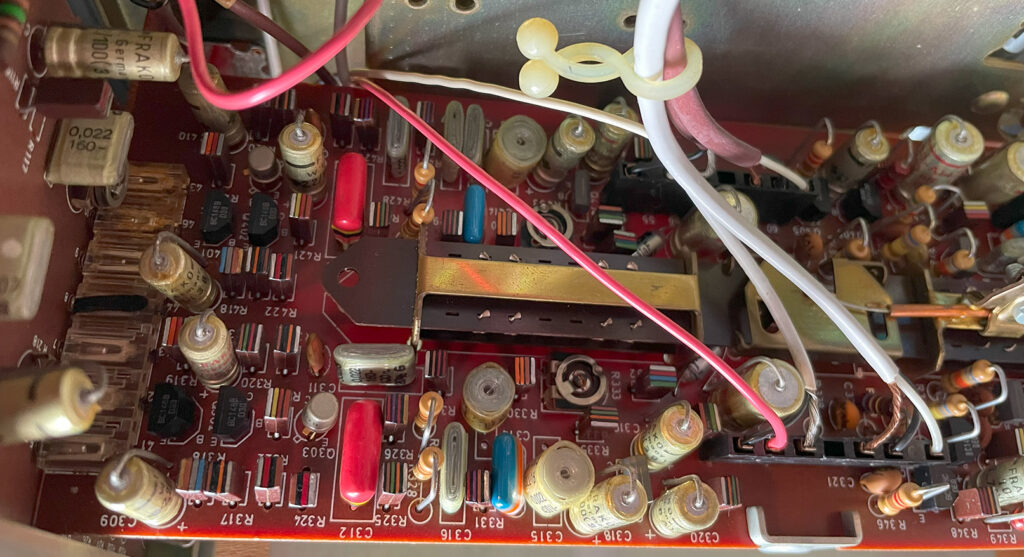

Main PCB board.

The main PCB is shown below.

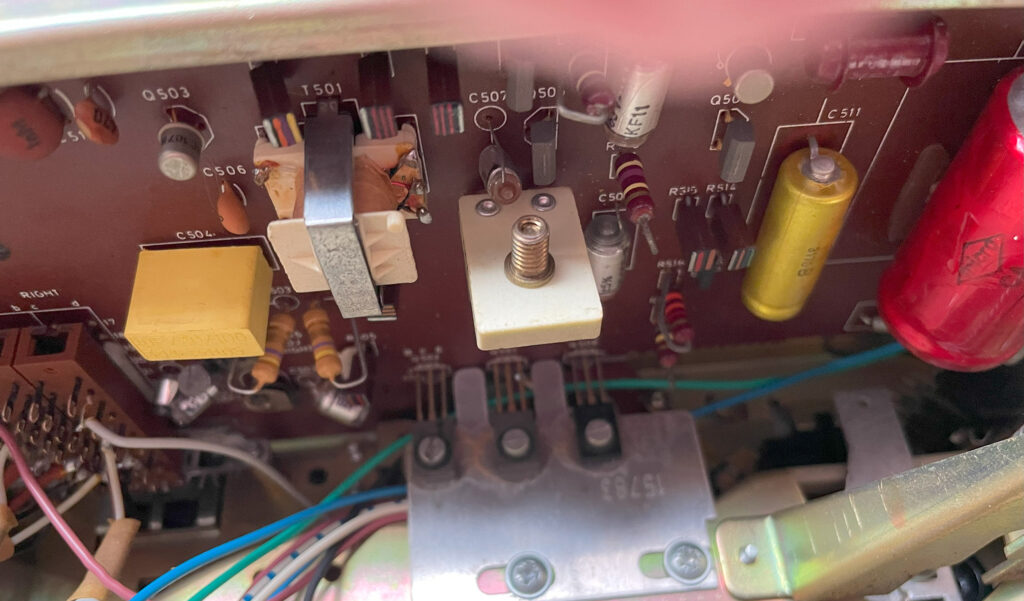

PSU board.

The power supply board.

Crossfield head recording.

The deck has four heads. Cross-field recording utilises a second head to record the bias signal separately from the signal. It is placed on the back of the tape directly opposite the recording head. Since the bias has to reach the deepest layers of the oxide, placing the head on the back of the tape means that reaching these levels does not require it to penetrate right to the front of the tape. This helps reduce self-erasure due to the bias signal.

The heads are arranged so the combination of the two signals results in a small “dead zone” directly past the recording head where high frequency signals are blanked out. This prevents subsequent high frequency signals from interfering with those just recorded, by the time they exit the dead zone they are too far from the head to be overwritten.

Spec:

Track system: 4-track, 2-channel, stereo/mono

Heads: 1 x record, 1 x playback, 1 x erase, 1 x bias

Motor: asynchronous

Reel size: 7 inch max

Tape speeds: 1 7⁄8 3 3⁄4 7 1⁄2 ips

Wow and flutter: 0.07% (7 1⁄2 ips)

Frequency response: 40Hz to 20kHz (7 1⁄2 ips)

Signal to Noise Ratio: 54dB

Total harmonic distortion: 0.5%

Crosstalk: 50dB

Input: 100mV (line), 0.1mV (mic)

Output: 0.75V (line)